UNDER-FLOOR HEATING – INTRO

The under-floor heating is known from antiquity. However applies only in recent decades. But demand has risen sharply due to the low price installation of the system which came to rival the installation of radiators. The advantages of under-floor heating over other heating methods are:

-Uniform temperature distribution on the premises.

-Uniform temperature distribution on the premises.

-Save space by avoiding radiator.

-Low-cost operation.

-Low water temperature.

-Use of alternative energy sources such as heat pump with very low running costs compared to oil and gas up to 60%.

The disadvantages are: -Need a dedicated scholar – installer.

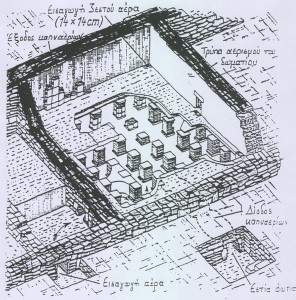

SYSTEM DESCRIPTION

The floor heating is a heating system with water at low temperature 45 ° C having a heating surface of the floor, in which multilayer pipes installed and aluminum. Offered for heating any space either independently or in conjunction with other systems (for example radiators) and cooling.

INSULATING MATERIAL

The panel (insulated floor slab), which shall be run under the floor heating is hard slabs of expanded polystyrene high density (30 Kg/m3), height 50mm, with quick support system for them to have easy and fast installation, stability, soundproofing, thermal insulation, mechanical strength, support tube, choice of distancetube (75 / 150 / 225 / 300mm), minimizing thermal bridges with special processing. I packaging are boxes of 10 m making it easy and safe (no damage) to transport them.

CONSTRUCTION

The floor heating installed after swabs and certainly before the final floor coverings.

The floor heating adds to the height of the floor 9 cm, for example where tile adhesive the total amount of floor heating insulating material – pipe – cement -tile reaches 9 cm, while in case of a marble floor, where the marble mounted with adhesive, the total amount of floor reaches 11 cm.

It is also possible and fitting wood floor buddy, where the thickness of wood can be up to 1, 5 cm. At the places where the floor heating will installed, will placed duct tape wall and insulating material. Mounted collectors (distributors), spread out (braided) the tube is cold, without joints, with a certain density, the study demonstrates that during heating to meet the heat loss of each area.

After the pipes –placement there’s a 24 hours check of the pipes under 6 bar pressure.

Immediately after the installation of pipes are monitored pressure 6 bar for 24 hours. Finally, the tubes covered with cement (thermompeton) 5 cm thick and the floor is ready to accept the final coat (marble, tile, wood, etc.)

B&T TUBE MULTILAYER 5 MATTRESSES GERMANY

The used types of plastic tubes are multilayer plastic tubes, or new technology multilayer aluminium, higher strength.

The aluminium tube is manufactured in Germany by aktinodiktyomeno high polyethylene molecular structure. Networked electron bombardment during the production phase and thus achieve full uniform mass of material by 100% (DIN 1689 / 3, SKZ, DVGW, ISO 9001). The outer shell is made of cross-linked polyethylene. The construction of the tube turns in higher strength, not kinked, with very little expansion and 100% oxygen barrier. This is the most important advantage of the pipe B & T vs. pipe, networked with chemical methods, in which raw materials are mixed and stirred just mechanically without the homogenization of the mass, can, reach high levels. The aluminium tube B & T is not a wrapped but welding the ends in front of a laser. During his placement on the floor need not be heated and, once installed, it gets easily shape obtained due to construction.

The placement of the circuit is strictly non-union in the floor. The advantages are:

- Withstand high temperature and pressure (10 bar l 6 bar I 95 ° C l 110 ° C).

- No aging

- It isn’t eroded of salts, antifreeze and various chemical additives in water.

- Not kinked – bent by hand up to 5 times the diameter.

- No tear, even if scratched.

- It’s unbreakable in shocks.

- Resistant to bending (minimum radius of curvature at O ° C = 8 times the diameter).

- It has less friction loss.

- It is quiet even at high flow rates.

- Not self igniting.

- Place cold without need to heat first.

- It is easy to handle, cutting and connecting.

- It has a very small coefficient of expansion.

- At the beginning of winter and a time may be destined for high water temperature without problem. In Greece more than 20, 000, 000 m. of tube have been placed.

JOINTS EXPANSION

During operation of under-floor heating have expansion and contraction of the floor. The contractions of these are around 4mm in length of about 10m and the conditions under which the work floor-heating. To reach these expansions is placed around the perimeter, each area, a wide, easy to compress film (thickness 1cmand height as the floor-heating and the final floor together)which called duct tape wall.

WARRANTY

The floor heating, accompanied by a guarantee of 10+30 years versus urban risk and amount of damage till 2, 500, 000 €. In case of damage, the damaged portion is repaired.The ten-year period has been limited by guarantee liability of the German public, and followed it in practice and the insurance companies of other European countries. The German government first addressed the issue, because the development of plastic pipe under-floor heating and floor-heating itself started predominantly from Germany.

The reasons for the economical operation of the floor heating system over another are:

The lowest water temperature of floor heating, which results in lower transmission losses, etc.

The milder but longer-lasting operation of the floor heating, which is practically required by the floor heating requires initial thermal accumulation on the floor and after radiation for heating

The fact that the floor heating, as heating by radiation, heating the corresponding range of radiation, and only the space in which man lives (till the height of 2, 20 m) and not the whole space, which is useless. Hence the floor heating is suitable for heating high spaces such as churches, stadiums, high rooms, outdoor spaces, rooms or living rooms with great height, etc.

Can be used instead of oil or gas boiler, electric heating unit (heat pump) where the efficiency varies from 300% to 610% so that we have reduced operating costs by up to 80%.

Can be used with solar collectors for aiding and full use of sunshine during the winter months.